China High Quality Peroxide Fluorovulcanized Rubber Factories – White elastomer Fluororubber DYF26 Series – DONGTAI

China High Quality Peroxide Fluorovulcanized Rubber Factories – White elastomer Fluororubber DYF26 Series – DONGTAI Detail:

Typital Properties

| Item | Unit | DYF2601 | DYF2602 | DYF2603 | DYF2604 | |

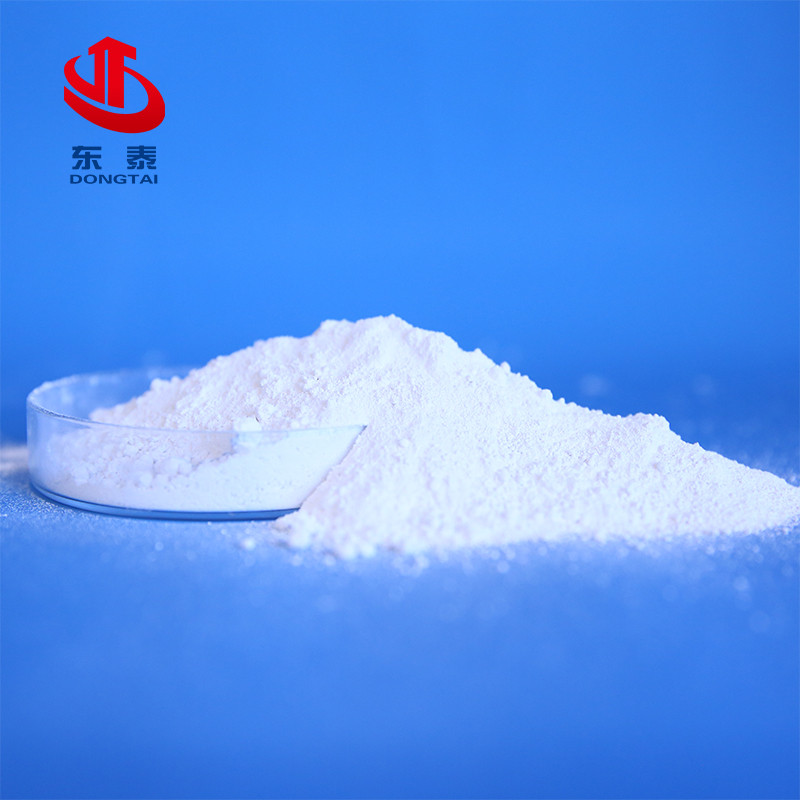

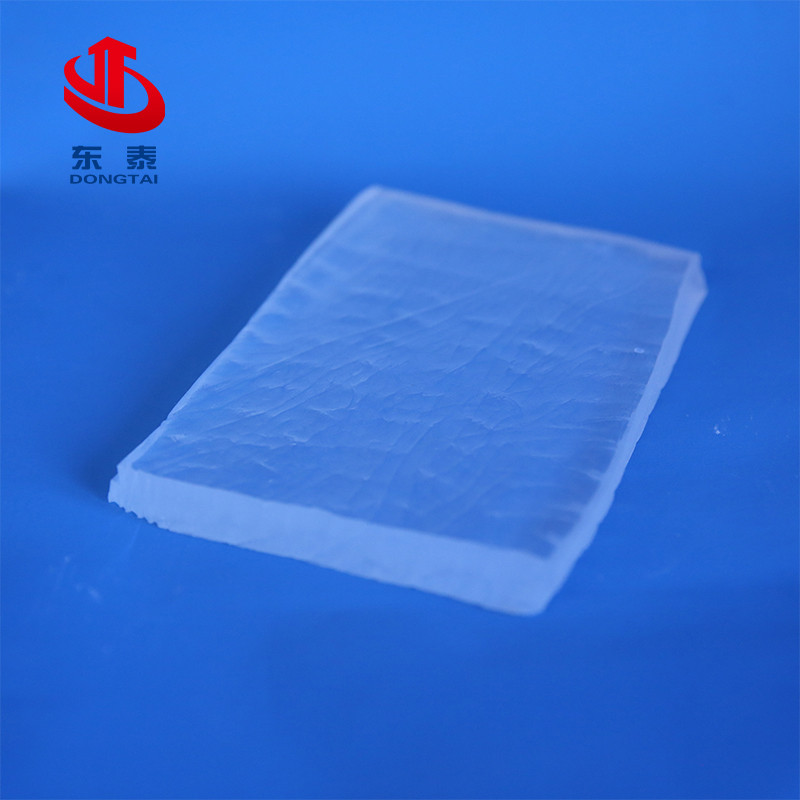

| Rubber | Appearance | White / Light Yellow rubber | ||||

| Relative density | g/cm³ | 1.80-1.84 | 1.80-1.84 | 1.80-1.84 | 1.80-1.84 | |

| Moisture | % | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | |

| Mooney viscosity[ML(1+10),121℃) | - | 10-40 | 41-60 | 61-100 | 101-200 | |

| Vulcanized Rubber | EN Compression Set(200℃, 70h) | % | ≤25 | ≤25 | ≤25 | ≤25 |

| Tensile strength | MPa | ≥11 | ≥11 | ≥11 | ≥11 | |

| Percentage of breaking elongation | % | ≥150 | ≥150 | ≥150 | ≥150 | |

| Hardness | SauerA | 70-80 | 70-80 | 70-80 | 70-80 | |

| Characteristic | Low Mooney viscosity,Polymer has good rheological properties | Middle mooney viscosity | Middle-high mooney viscosity,Good ductility and malleability | High mooney viscosity,High mightiness | ||

| Application | High mooney viscosity rubber,reduce viscosity additive,0 ring, Anti-extrusion part of synthetic products |

|

Mixing diaphragm,Oil seal,Squeeze type hose etc. | Injection Molding’s components,Processing system’s oil seal etc. | ||

Note:In the identification formula, bisphenol AF curing agent is used for vulcanization test

application

It is widely used on heat-resistance,fuel resistance(aviation fuel, automobile fuel), gasoline-proof grease

(various of synthetic oils), fluid resistance (various of non-polar solvents), corrosion resistance (acid, alkali), strong oxidant resistance (Sulfur trioxide, etc.), ozone resistance, radiation resistance,

In the case of atmospheric aging, make gaskets, gaskets, O-rings, V-shaped bodies, skeleton oil seals, diaphragms, hoses, cable sheaths, insulation cloths, valves, expansion joints, rubber rollers, coatings, paste room temperature vulcanization Putty etc.

Package, Transport and Store

1.Fluororubber store in clean,dry,cool warehouse.It is non-hazardous chemicals,pls far away from pollution, sunshine and water.

2.The product storage period one year since the productions.If beyond storage,it can according to our company standard to test it,if it is ok,then it can continue use it.

Attention

★ Fluororubber have good heat stability under 260℃;If keep long time between 260℃ and 300℃,it will micro-decomposition;More than 320℃,the product will decompose very fast and the decomposition product are toxic hydrogen fluoride and fluorocarbon Organic compound.When fluororubber encounters flame, it will also releases toxic hydrogen fluoride and fluorocarbon organic compounds.

★ Fluororubber can not mix with metal powder(Al powder,MG powder etc.) or more than 10% Amine compound,otherwise it will react violently with fluorine rubber due to some elements,rubber material temperature will rose rapidly,then it will take big damage to mixing equipment and operator.

Product detail pictures:

Related Product Guide:

We keep on with the basic principle of "quality to start with, support very first, continuous improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for China High Quality Peroxide Fluorovulcanized Rubber Factories – White elastomer Fluororubber DYF26 Series – DONGTAI , The product will supply to all over the world, such as: Italy, Qatar, Marseille, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!