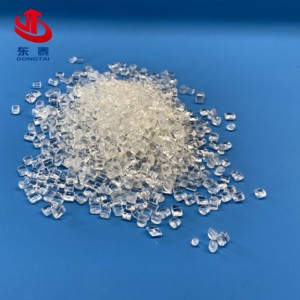

Chemical Recycled Cationic PET chips

|

Serial number |

Item |

Unit |

Quality index |

Test result |

|

|

1 |

Intrinsic viscosity |

dL/g |

0.39± 0.01 |

0.375 |

|

|

2 |

Melting point |

℃ |

200±5 |

203 |

|

|

3 |

Terminal carboxyl content |

mol/t |

≤35 |

23 |

|

|

4 |

Color |

B |

— |

≥60 |

70 |

|

L |

— |

4±2 |

4.5 |

||

|

5 |

(SIPA) |

% |

11.0±0.3 |

11.1 |

|

|

6 |

(Ti)Ti content |

PPM |

- |

6 |

|

|

7 |

Moisture(mass fraction) |

% |

≤0.6 |

0.35 |

|

|

8 |

Diethylene glycol content(mass fraction) |

% |

3.5±0.5 |

3.3 |

|

|

9 |

Ash content |

% |

≤0.15 |

0.12 |

|

|

10 |

Powder |

mg/kg |

≤100 |

50 |

|

|

11 |

Abnormal slice(mass fraction) |

% |

≤0.4 |

0.2 |

|

Spinning various polyester fiber products;Cationic modification improves the dyeing performance of polyester fibers, and CDP fabrics can be deeply dyed with cationic dyes under high temperature and pressure; NPCDP fabric can be deeply dyed with cationic dyes at normal temperature and pressure.Fast dyeing, high dyeing fastness, bright color, can be blended with other fibers to obtain fabrics of different shades and styles;Especially fibers with special-shaped cross-sections can be processed into high-grade wool-like fabrics with full handle.

Packed in PP woven bag lined with PE bag.It should be stored in ventilated and dry warehouses according to different batch numbers and grades, and fire-fighting facilities should be installed in the warehouses.Keep away from open flames and heat sources during storage and transportation;Do not mix with oil, acid, alkali and other chemicals for storage and transportation;Measures should be taken during loading and unloading to avoid package damage and personal injury.

The central value of the currently provided product quality indicators can be adjusted appropriately according to users’ needs.

If there is a new version of the currently provided product standards and test method standards, the latest version shall prevail.